Powder Coat vs Automotive Paint — Which Is Right for Your Business?

When distributors, body shops, fleet owners, or repair shops weigh options for finishing vehicle components they often face a core question: powder coat vs automotive paint — which one should I choose, and why? Both finishing systems have strong advantages, but they serve different applications, require different equipment and skills, and deliver different long-term value depending on the job. Below is a clear, practical comparison to help you decide and to show how choosing the right supplier—one that understands distributors’ needs—makes all the difference.

What powder coating is (quick overview)

Powder coating uses a dry powder (thermoplastic or thermoset) applied electrostatically and then cured in an oven. It produces a tough, uniform finish that’s resistant to chips, chemicals, and corrosion. Powder coatings are widely used for wheels, hardware, brackets, rims, engine components, frames, and many industrial parts. The process is efficient for high volumes and for parts that can be baked at elevated temperatures.

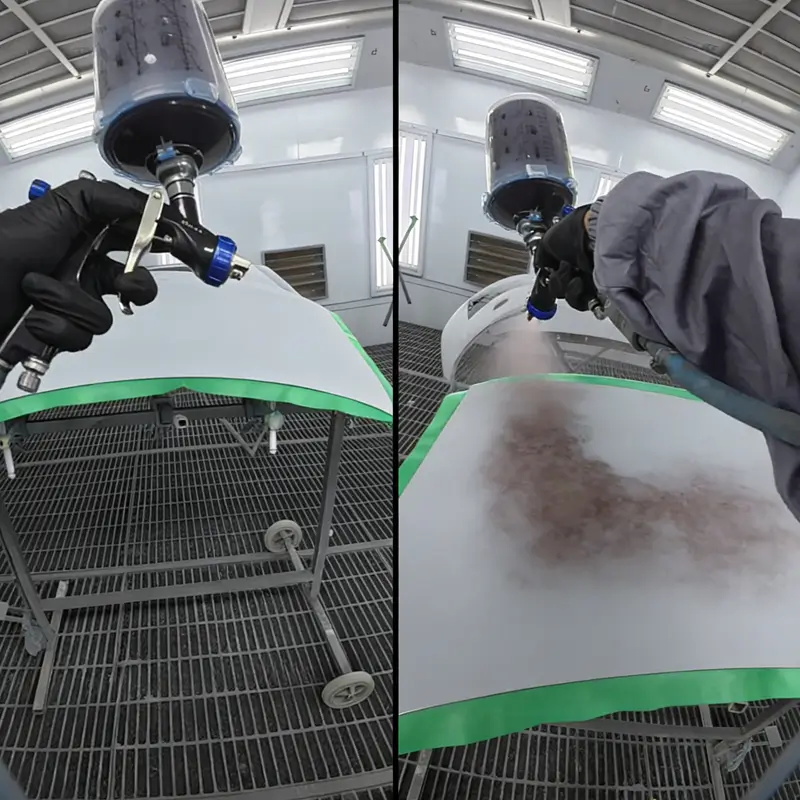

What automotive paint is (quick overview)

Automotive paint refers to the wet paint systems used to finish car bodies and components: basecoats (color), clearcoats, primers, single-stage or two-stage systems, and specialty coatings. Automotive refinish paint is formulated for color accuracy, gloss, depth, and repairability. It is sprayed, flash-cured, and often requires drying or baking depending on the system (1K air-dry, 2K catalyzed systems, etc.). Modern automotive paint systems are engineered for OEM-style appearance and seamless blending during repairs.

Key differences: powder coat vs automotive paint

Appearance and depth

- Automotive paint (with basecoat + clearcoat) offers deeper, glossier finishes and superior effect colors (pearlescent, metallic, candy) and is the industry standard where showroom appearance and color matching are essential.

- Powder coat gives a very durable, uniform surface but traditionally lacked the deep, wet-look gloss and complex effect colors; recent powder technology improved finishes, but automotive paint still leads for high-end visual depth.

Durability and resistance

- Powder coating is exceptionally tough against abrasion, corrosion and chipping — ideal for wheels, underbody parts, and exposed metalwork.

- Automotive paint with high-quality clearcoat provides excellent UV resistance and gloss retention but can be more susceptible to chips versus a heavy powder build in high-impact areas.

Repairability

- Automotive paint wins in repairability. Spot repairs, blending, and color matching in collision repair are straightforward with liquid refinish systems.

- Powder coat repairs are more difficult: repaired areas usually require stripping and re-baking or creative mechanical repairs; spot painting is rarely seamless.

Application and equipment

- Powder coating requires electrostatic application and ovens sized for parts — good for batch/production lines.

- Automotive paint requires spray booths, mixing systems and trained sprayers. Refinish shops and OEM lines have different infrastructure needs — both require quality control and safety measures.

Color matching & variety

- Automotive paint systems provide extensive color matching systems and tinting capability tailored to automotive OEM colors.

- Powder coat color matching has improved but is still more limited for complex automotive colors and effects.

Environmental and regulatory

- Powder coating is often promoted as low-VOC because it’s a dry process and overspray can be reclaimed, making it attractive where VOC regulation is strict.

- Automotive waterborne and low-VOC solvent systems have advanced significantly and are now common in refinish and OEM environments. Distributors must consider local VOC regulations and customer preferences.

Cost & throughput

- For high volumes of identical parts, powder coating can reduce labor and waste and deliver low per-part cost.

- For body panels and color-critical work, automotive paint systems are necessary despite potentially higher material cost and more labor at the point of application.

How to choose (practical guidance for distributors)

1. Define the end use: wheels and brackets → powder coat; body panels and refinish → automotive paint.

2. Consider repair and aftermarket needs: collision repairers need liquid refinish systems for blending.

3. Equipment & space: evaluate whether your customers have ovens (powder) or spray booths (paint).

4. Color flexibility: if customers demand pearlescent or OEM matches, prioritize automotive paint systems.

5. Regulations & sustainability: compare VOC requirements and waste handling preferences.

6. After-sales support: technical training, tinting systems, and quick sample availability matter for distributors.

Why the supplier matters — what distributors care about

Distributors choose a manufacturer not only for product specs but for: consistent quality, stable lead times, clear MOQ and pricing, technical support (spray protocols, mixing ratios), color matching systems, training offerings, packaging for resale, and trustworthy warranty and claims handling. A reliable supplier that sells direct from the factory (no middlemen) lowers cost, shortens supply chain and improves responsiveness.

SYBON: Your Partner for Automotive Refinish and Wholesale Auto Paint

At SYBON we understand distributor priorities because we’re a professional automotive paint manufacturer focused on professionalism, efficiency, and integrity. We manufacture high-performance automotive paints and related refinish products (including putties and ancillary items) and deliver them directly to distributors and dealers—no middlemen—so you get factory pricing, consistent quality, and a predictable supply chain.

Why distributors and repair shops choose SYBON:

- We balance outstanding product quality with competitive pricing, offering a value proposition close to big brands while delivering excellent cost performance for regional markets.

- SYBON supports one-stop procurement: paints, primers, clearcoats, putty and accessories—convenient for shops that want a single supplier for refinish lines.

- We provide technical support, color matching help, mixing ratios and training resources to help your customers achieve reliable results.

- SYBON products have received strong feedback from dealers and fleet owners; our focus is on durable finishes, accurate color, and ease of use in repair environments.

If you’re a distributor, paint shop owner, repair center manager or fleet operator looking for premium automotive refinish products without the premium price tag, SYBON is ready to partner. We are actively seeking global distributors and welcome sample requests and distributor inquiries. Request samples to test in your local process—our products are factory-produced, shipped directly, and designed to help you compete locally with high value.

To start a partnership, send an email through our website contact form and we’ll respond within 24 hours. Let SYBON help you expand product offerings, improve margins and deliver dependable refinish solutions to your customers.

Source of this article:https://www.supersybon.com/

Get to know us through more channels: