Home - Products - Car Body Filler - Fiberglass Body Filler

Car Body Filler Series

Lightweight Body Filler

BPO Polyester Putty

CHPO Polyester Filler

High-Temp Filler

Fiberglass Body Filler

1K Nitrocellulose Putty

1K Primer Surfacer

1K Plastic Primer

2K Intermediate Primer

2K Epoxy Primer

Auto Paint Series

Auto Repair Series

View All Products

CONTACT US

Fiberglass Body Filler

Discover the pinnacle of excellence in automotive restoration with SYBON Fiberglass Body Filler. Crafted to perfection, our product is a testament to innovation, quality, and performance. Specially designed for tackling substantial challenges, this filler redefines the art of restoration.

Product Features:

· Masterful Repair: SYBON Fiberglass Body Filler stands as the ultimate solution for addressing large cracks, deep scratches, holes, and other significant defects in glass fiber reinforced plastic parts, automobile bumpers, and welded plate substrates. Experience seamless restoration as you breathe life back into your prized vehicles.

· Advanced BPO System: Powered by an imported Benzoyl Peroxide (BPO) system, our filler offers unrivaled filling capacity and anti-shrink properties. This means confidence in each application, with assurance that your restoration work remains intact for the long haul.

· Adhesion at its Best: Trust in the remarkable adhesion of SYBON Fiberglass Body Filler. Whether it's iron plate, steel plate, stainless steel plate, aluminum plate, glass steel, or metal surfaces with primer, our filler forms a bond that ensures your restoration projects withstand the test of time.

· Superior Sanding: Achieve flawlessness with ease. Our filler boasts excellent sandability, allowing you to shape and refine your restoration work to perfection. Say goodbye to uneven surfaces and hello to a finish that rivals professional craftsmanship.

Transform your restoration endeavors with SYBON Fiberglass Body Filler. Revive the beauty and integrity of your vehicles with a product that defines excellence. Visit our official website today and explore the full range of SYBON products designed to turn your restoration dreams into reality.

Contact Details

No 4, Chengye Road, Daliang, Shunde, Foshan, Guangdong, China

+86 13682292799

www.supersybon.com

sales@supersybon.com

SOCIAL

Contact Us

Enquiry will send to our sales team, we will reply you with 24 hours.

Need Any Help ?

Order or no-order we are always here to help you

Elevate Your Business with Premium Fiberglass Body Filler

Are you ready to elevate your business offerings to new heights? SYBON is excited to introduce two dynamic collaboration models designed to amplify your success in the automotive restoration industry. As a prominent name in the field, SYBON presents not just products, but strategic partnerships that cater to your unique business needs.

1. Distributorship of SYBON Brand Fiberglass Body Filler:

Join hands with a trusted innovator in automotive restoration. Our Fiberglass Body Filler stands as a benchmark of excellence, known for its quality, versatility, and advanced technology. By becoming a distributor of SYBON's renowned brand, you gain access to a product lineup that empowers your clientele with top-tier solutions for their restoration projects. Enhance your reputation as a provider of premium products, backed by SYBON's expertise and commitment to perfection.

2. Custom Packaging Collaboration:

Customization meets collaboration in this unique opportunity. SYBON presents a mode where we provide you with our premium Fiberglass Body Filler products in blank packaging. This allows you to infuse your brand identity by affixing your logo onto the packaging, presenting a seamless extension of your business. With this partnership, you bring SYBON's exceptional quality under your brand's umbrella, establishing your authority in the market.

Why Choose SYBON Partnership:

Quality Assurance: SYBON is synonymous with uncompromising quality. Our products undergo rigorous testing to ensure they meet and exceed industry standards, ensuring your customers' satisfaction.

Expertise and Support: Benefit from our years of experience in automotive restoration. Our team offers comprehensive support, technical expertise, and guidance to ensure your success.

Versatile Solutions: Whether you're a distributor or custom packaging collaborator, SYBON's solutions cater to various business models, enhancing your business's potential.

Innovation at Core: SYBON is a hub of innovation, constantly developing cutting-edge solutions that push the boundaries of automotive restoration technology.

Unlock new horizons for your business with SYBON. Join us in redefining the automotive restoration landscape. Contact us today to discuss which partnership model suits your goals best and embark on a journey of growth and success.

CONTACT US

Enquiry will send to our sales team, we will reply you with 24 hours.

Unveiling the Power of Fiberglass Body Filler: A Complete Guide

What is Fiberglass Body Filler and How Does It Work?

What are the Advantages of Using Fiberglass Body Filler in Automotive Restoration?

Which Types of Defects and Damage Can Fiberglass Body Filler Effectively Repair?

What Surfaces Can Fiberglass Body Filler Adhere to, Apart from Glass Fiber Reinforced Plastic?

How Can Professionals Achieve Seamless Blends and Contours with Fiberglass Body Filler?

What Factors Should I Consider When Choosing the Right Fiberglass Body Filler for My Project?

Challenges when using Fiberglass Body Filler in different weather?

How Does SYBON Ensure Quality and Consistency in Their Fiberglass Body Filler Products?

Are There Any Step-by-Step Tutorials for DIY Enthusiasts on Applying Fiberglass Body Filler?

What is Fiberglass Body Filler and How Does It Work?

Automotive restoration is an art that demands precision, craftsmanship, and the right tools. At SYBON, we understand the significance of excellence in restoration, and that's why we bring you a comprehensive guide to understanding Fiberglass Body Filler and its intricate workings.

Defining Fiberglass Body Filler:

Fiberglass Body Filler is a specialized product designed to mend imperfections, restore structural integrity, and provide a seamless finish to various surfaces. It's a vital component in automotive restoration, catering to tasks ranging from repairing large cracks and deep scratches to addressing holes and other substantial defects. This filler acts as a bridge between damaged surfaces and their original state, enhancing both appearance and functionality.

How Fiberglass Body Filler Works:

The magic of Fiberglass Body Filler lies in its unique composition and application process. Let's dive into the step-by-step breakdown of how this remarkable product works:

Preparation of the Surface:

Before applying Fiberglass Body Filler, the damaged area must be prepared meticulously. This involves cleaning, sanding, and ensuring a smooth surface for optimal adhesion.

Mixing the Filler:

Fiberglass Body Filler comes in a two-part system, typically consisting of a resin and a hardener. These components are mixed in precise ratios to initiate a chemical reaction that leads to curing.

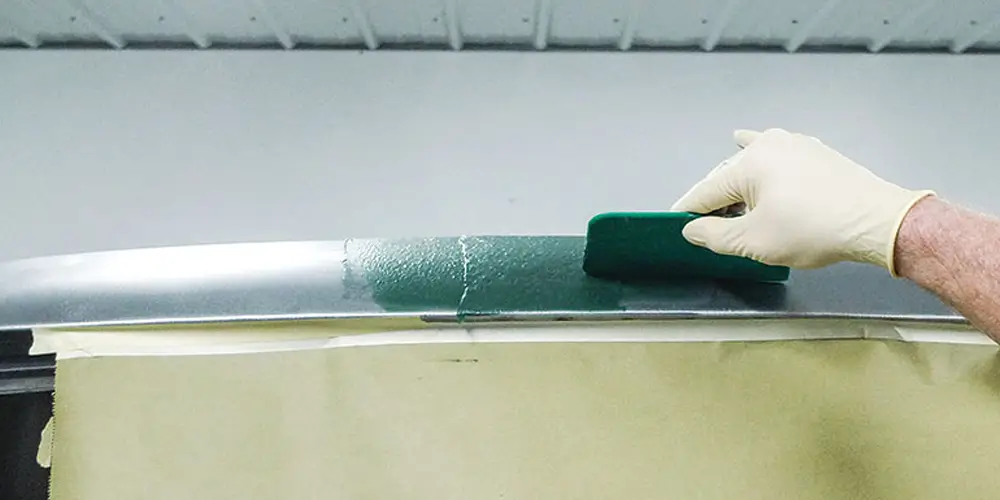

Application:

Once mixed, the filler is applied to the damaged area using specialized tools such as putty knives or spatulas. It's spread evenly, filling in gaps, cracks, and imperfections.

Sanding and Shaping:

After the filler cures, it's sanded down to achieve a seamless blend with the surrounding surface. This step requires skill to create contours that match the original design of the vehicle.

Priming and Painting:

The sanded and shaped area is primed to ensure a consistent surface for paint adhesion. Once primed, the area can be painted to match the rest of the vehicle seamlessly.

The Science Behind the Filler:

Fiberglass Body Filler's efficacy is owed to its formulation. It typically contains a combination of resin, fillers, and strengthening agents. The resin acts as a bonding agent, adhering to the substrate, while fillers like talc or microspheres provide bulk and enhance sanding properties. Strengthening agents such as fiberglass strands add structural integrity.

SYBON's Commitment to Excellence:

As a leading manufacturer in the industry, SYBON takes pride in crafting Fiberglass Body Filler of the highest quality. Our products undergo rigorous testing to ensure superior adhesion, sanding capabilities, and durability. The culmination of cutting-edge technology, expert craftsmanship, and meticulous quality control results in a filler that stands as a testament to restoration perfection.

In conclusion, Fiberglass Body Filler is a transformative tool in automotive restoration. Its intricate process involves preparation, mixing, application, sanding, and priming to achieve flawless results. SYBON's dedication to innovation and quality ensures that our Fiberglass Body Filler is the ultimate choice for professionals and enthusiasts alike, as it elevates the art of automotive restoration to new heights.

What are the Advantages of Using Fiberglass Body Filler in Automotive Restoration?

Automotive restoration is a delicate art that demands the perfect blend of skill, technology, and precision. When it comes to restoring and revitalizing vehicles, one indispensable tool stands out: Fiberglass Body Filler. At SYBON, we take immense pride in elucidating the myriad advantages that Fiberglass Body Filler brings to the world of automotive restoration.

1. Seamlessly Repairs Imperfections:

Fiberglass Body Filler serves as a magician's wand when it comes to addressing imperfections. It adeptly mends cracks, scratches, and dents of varying sizes, restoring the structural integrity of the damaged area. This ability to seamlessly repair a wide range of defects ensures that the vehicle regains its original form and function.

2. Restores Aesthetics:

The aesthetic appeal of a vehicle is paramount. Fiberglass Body Filler enables restorers to achieve impeccable finishes that blend seamlessly with the original design. Whether it's a classic car, a vintage motorcycle, or a modern automobile, the filler's capacity to create smooth contours ensures a visual harmony that's hard to discern from the original.

3. Versatile Application:

One of the standout advantages of Fiberglass Body Filler is its adaptability to various substrates. Whether the surface is metal, plastic, this versatile filler forms a robust bond that withstands the test of time. It becomes an all-encompassing solution that caters to diverse restoration projects.

4. Precision Sanding:

Craftsmanship is an integral part of automotive restoration, and Fiberglass Body Filler facilitates this by allowing precision sanding. This means that restorers can meticulously shape and refine the repaired area until it achieves a flawless surface. The ability to seamlessly integrate repairs with the original contours is a hallmark of professional restoration.

5. Enhanced Structural Integrity:

Fiberglass Body Filler isn't just about surface-level fixes. It contributes significantly to the vehicle's overall strength. The filler's formulation often incorporates strengthening agents like fiberglass strands, imparting durability and robustness to the repaired area. This ensures that the vehicle maintains its integrity even after restoration.

6. Quick Turnaround:

Time is of the essence, especially in automotive restoration. Fiberglass Body Filler offers a quick-drying solution, reducing the time gap between application and sanding. This accelerates the restoration process, enabling professionals to undertake more projects while maintaining the same high standards of quality.

7. Professional-Grade Results:

Fiberglass Body Filler bridges the gap between DIY enthusiasts and professional restorers. Its ease of application, coupled with its ability to yield professional-grade results, empowers both amateurs and experts to achieve flawless finishes. This democratization of excellence is one of the hallmarks of modern automotive restoration.

In the realm of automotive restoration, Fiberglass Body Filler reigns as an indispensable tool. Its advantages extend beyond mere repairs, encompassing aesthetics, strength, versatility, and efficiency. At SYBON, we've harnessed these advantages to craft a Fiberglass Body Filler that embodies the essence of restoration excellence. Join us in elevating the art of automotive restoration to new dimensions.

Which Types of Defects and Damage Can Fiberglass Body Filler Effectively Repair?

Automotive restoration is an intricate dance between time, expertise, and the right tools. In this pursuit, Fiberglass Body Filler emerges as an unsung hero, capable of addressing a wide array of defects and damages that vehicles may bear. At SYBON, we're dedicated to shedding light on the expansive scope of restoration made possible by our Fiberglass Body Filler.

1. Cracks and Fractures:

Cracks, whether small or substantial, are a common challenge in automotive restoration. Fiberglass Body Filler adeptly fills and bonds to cracks, preventing them from worsening and restoring structural integrity. This versatile filler ensures that cracks become a distant memory as vehicles regain their strength.

2. Deep Scratches:

Superficial scratches may mar a vehicle's appearance, while deep scratches can compromise its aesthetics and resale value. Fiberglass Body Filler comes to the rescue, smoothing and leveling the damaged area. By erasing scratches, the filler seamlessly blends the repaired portion with the rest of the surface.

3. Holes and Punctures:

Holes resulting from accidents, rust, or other factors can seriously compromise a vehicle's integrity. Fiberglass Body Filler's robust filling capacity bridges these gaps, providing a solid foundation for subsequent finishing layers. This effective hole-repair mechanism resurrects the vehicle's durability.

4. Dents and Dings:

From parking lot mishaps to minor collisions, dents and dings are inevitable. Fiberglass Body Filler's pliability allows it to contour to the shape of the dent, restoring the original form. This eliminates the need for extensive metalwork and helps retain the vehicle's originality.

5. Surface Imperfections:

Fiberglass Body Filler is an expert at transforming uneven surfaces. Whether it's rough patches, divots, or irregularities, the filler evens out the surface, allowing for smooth finishes during painting. This meticulous attention to detail ensures that the final restoration is nothing short of perfection.

6. Missing Sections:

In cases where sections of the vehicle are missing or damaged beyond repair, Fiberglass Body Filler can play a pivotal role. By building up layers of the filler, restorers can recreate missing sections, seamlessly integrating them with the original design.

7. Weld and Seam Imperfections:

Restoring a vehicle often involves welding and seam work, which can leave uneven gaps. Fiberglass Body Filler steps in to smoothen these transitions, ensuring that the final surface is uniform. This finishing touch prevents unsightly gaps and elevates the overall restoration quality.

8. Restoration Details:

Fiberglass Body Filler's precision extends to intricate details like contours, edges, and curves. It can be used to refine these areas, ensuring that the restored vehicle reflects the original craftsmanship.

In essence, Fiberglass Body Filler is a chameleon of restoration, adapting to the unique challenges each project presents. From cracks to dents, scratches to holes, its effectiveness spans a spectrum of defects and damages. At SYBON, we've harnessed this versatility to create a product that caters to every restoration need. Join us in transforming vehicles from the brink of despair to the pinnacle of revival.

What Surfaces Can Fiberglass Body Filler Adhere to, Apart from Glass Fiber Reinforced Plastic?

In the realm of automotive restoration, versatility is key. As a leading manufacturer of Fiberglass Body Filler, known as SYBON, we're committed to unraveling the incredible adaptability of our product. Beyond its renowned use with Glass Fiber Reinforced Plastic (GRP), our Fiberglass Body Filler extends its grip to an array of surfaces, offering a transformative solution for a wide range of restoration projects.

1. Metal Surfaces:

Fiberglass Body Filler's adhesive prowess is not confined to plastics alone. It establishes a strong bond with various metal surfaces, such as iron, steel, stainless steel, and aluminum. Whether it's restoring a vintage car's metal body or a motorcycle's steel frame, the filler seamlessly adheres to metal substrates.

2. Plastic Components:

Beyond Glass Fiber Reinforced Plastic, Fiberglass Body Filler also exhibits compatibility with other plastic materials used in automobiles. From bumper repairs to interior panels, the filler's adhesion ensures that the restoration work blends seamlessly with the original plastic components.

3. Primed Metal and Surfaces:

Primed metal surfaces serve as the perfect canvas for Fiberglass Body Filler's excellence. Whether for structural components or aesthetic parts, the filler adheres effectively to primed surfaces. This quality ensures that the restoration integrates seamlessly into the vehicle's overall design.

4. Restoring Stainless Steel Elegance:

Stainless steel components often grace classic and modern vehicles alike. Fiberglass Body Filler's ability to bond with stainless steel ensures that restoration endeavors involving these components are nothing short of exceptional.

5. Aluminium Advantages:

Lightweight and corrosion-resistant, aluminum is a favorite material for modern vehicles. Fiberglass Body Filler's compatibility with aluminum empowers restorers to address imperfections in aluminum parts, restoring both form and function.

6. Glass-Reinforced Plastic (GRP) Mastery:

Of course, the filler's original expertise shines when working with Glass Fiber Reinforced Plastic. Whether it's vintage car bodies, boat hulls, or other GRP components, the filler excels in repairing, reshaping, and enhancing these surfaces.

7. Cosmetic and Structural Applications:

From cosmetic enhancements to structural reinforcements, Fiberglass Body Filler's adaptability extends to various purposes. Whether it's adding strength to a metal component or achieving a flawless surface finish on plastic, the filler proves its worth.

SYBON's Fiberglass Body Filler isn't just a solution; it's a versatile asset that aligns with the dynamic demands of automotive restoration. Its ability to bond with diverse surfaces ensures that restorers can tackle a spectrum of projects with confidence. At SYBON, we take pride in crafting a product that upholds the principles of excellence, innovation, and versatility. Join us in transforming the restoration landscape and breathing new life into vehicles across the spectrum of materials and substrates.

How Can Professionals Achieve Seamless Blends and Contours with Fiberglass Body Filler?

Automotive restoration is a fusion of science and art, where attention to detail can make or break the final outcome. One of the critical skills in this realm is achieving seamless blends and contours, ensuring that the repaired areas seamlessly integrate with the rest of the vehicle. At SYBON, we delve into the artistry behind using Fiberglass Body Filler to attain these professional-grade results.

1. Meticulous Surface Preparation:

The foundation of seamless blending begins with meticulous surface preparation. Professionals understand the significance of clean, smooth, and properly sanded surfaces. Removing contaminants, rust, and old paint not only ensures proper adhesion but also provides a clean slate for applying the filler.

2. Mixing and Consistency:

The art of blending starts even before the filler touches the surface. Professionals pay careful attention to the mixing process, ensuring that the filler components are thoroughly blended to achieve a consistent texture. This uniformity is vital for achieving smooth transitions.

3. Feather Edges:

Creating seamless blends involves creating feathered edges around the repaired area. Professionals skillfully taper the edges of the filler, gradually transitioning from the repaired portion to the surrounding surface. This gradual transition minimizes the appearance of visible edges and contours.

4. Applying in Thin Layers:

Seasoned professionals understand that achieving seamless contours requires applying Fiberglass Body Filler in thin layers. By building up the filler in layers, they can sculpt and shape the repaired area with precision, avoiding abrupt changes in contour.

5. Patience in Sanding:

Sanding is a meticulous process that requires patience and finesse. Professionals use varying grits of sandpaper to gently shape the filler and blend it with the original surface. This step demands a delicate touch to avoid over-sanding or creating uneven surfaces.

6. Visual Inspection and Adjustment:

Professionals frequently step back to assess their work visually. They scrutinize the contours and transitions, identifying any discrepancies or imperfections. If adjustments are needed, they make them at this stage before proceeding further.

7. Seamless Primer Application:

Applying primer is a strategic step to ensure paint adhesion and a uniform finish. Professionals apply primer not just to the repaired area, but also to the surrounding surface. This helps achieve a seamless appearance when the final coat of paint is applied.

8. Art of Painting:

Seamless blending extends to the painting phase. Professionals pay attention to factors such as paint type, color matching, and technique to ensure that the repaired area seamlessly blends with the rest of the vehicle's surface.

SYBON's Role in Achieving Perfection:

Behind every successful professional lies the support of quality products. SYBON's Fiberglass Body Filler plays a pivotal role in achieving seamless blends and contours. Its formulation, workability, and ability to adhere to various surfaces provide professionals with the canvas they need to craft restoration masterpieces.

In conclusion, achieving seamless blends and contours in automotive restoration is a craft that demands skill, precision, and the right tools. SYBON's Fiberglass Body Filler stands as an ally for professionals in this journey, offering a medium through which their expertise can shine. Together, with the synergy of craftsmanship and innovation, we continue to elevate the art of automotive restoration to new dimensions of excellence.

What Factors Should I Consider When Choosing the Right Fiberglass Body Filler for My Project?

Embarking on an automotive restoration project is a journey of precision, creativity, and commitment. Central to this endeavor is the selection of the right tools and materials, with Fiberglass Body Filler playing a pivotal role. As a dedicated manufacturer, SYBON is here to guide you through the essential factors to consider when choosing the perfect Fiberglass Body Filler for your project.

1. Type of Repair:

The first step in selecting the right Fiberglass Body Filler is assessing the type of repair you're undertaking. Are you addressing cracks, dents, scratches, or more substantial damage? Different fillers have varying capabilities, and choosing one tailored to your specific needs ensures optimal results.

2. Substrate Compatibility:

Consider the material of the substrate you're working on. Is it metal, plastic, or fiberglass? SYBON's Fiberglass Body Filler is renowned for its versatility, adhering seamlessly to metal, plastic, and other surfaces. Ensuring compatibility is crucial to achieving a strong and lasting bond.

3. Adhesion and Bond Strength:

The adhesion of the filler to the substrate is paramount. Look for a filler with strong adhesion properties, as it ensures that the repaired area remains intact and structurally sound. SYBON's Fiberglass Body Filler boasts excellent adhesion, providing a reliable foundation for your restoration work.

4. Sanding and Shaping Abilities:

Professionals understand the significance of a filler's sanding and shaping capabilities. A high-quality filler should be easy to sand and shape, allowing you to achieve smooth transitions and contours. SYBON's filler excels in sanding, enabling you to achieve professional-grade finishes.

5. Curing Time:

The time it takes for the filler to cure varies between products. Consider your project's timeline and select a filler that aligns with your schedule. SYBON's Fiberglass Body Filler strikes a balance between efficient curing and allowing ample time for shaping and refining.

6. Environmental Factors:

Think about the environment in which the restoration will take place. Does the project require a filler with weather resistance, or will it be exposed to harsh conditions? SYBON's Fiberglass Body Filler exhibits excellent durability and weather resistance, ensuring long-lasting results.

7. Professional or DIY Use:

Your level of expertise matters when choosing a filler. Professionals might require a filler with advanced properties for intricate projects, while DIY enthusiasts might opt for a user-friendly option. SYBON's Fiberglass Body Filler caters to both ends of the spectrum, empowering professionals and beginners alike.

8. Manufacturer Reputation:

A reputable manufacturer ensures quality and consistency. SYBON's legacy of excellence in automotive restoration speaks for itself. Our Fiberglass Body Filler undergoes rigorous testing and adheres to industry standards, assuring you of a product that lives up to its promises.

SYBON's Commitment to Your Vision:

At SYBON, we understand that every restoration project is unique. Our Fiberglass Body Filler is engineered with these considerations in mind. From adhesion to compatibility, we've meticulously crafted a product that addresses every factor, enabling you to restore vehicles with precision and confidence.

In conclusion, the choice of Fiberglass Body Filler is a critical decision that shapes the success of your automotive restoration project. By factoring in repair type, substrate, adhesion, sanding abilities, and more, you're poised to make an informed decision. With SYBON's Fiberglass Body Filler as your ally, you're equipped to embark on a journey that transforms vehicles into works of art.

Challenges when using Fiberglass Body Filler in different weather?

Automotive restoration is a pursuit that transcends seasons and weather conditions. As professionals and enthusiasts strive for excellence, one of the challenges that surfaces is the impact of varying weather on the application and performance of Fiberglass Body Filler. At SYBON, we're committed to unraveling these challenges and providing insights into how our Fiberglass Body Filler tackles them head-on.

1. Temperature Extremes:

Temperature plays a pivotal role in the curing process of Fiberglass Body Filler. Extreme heat or cold can accelerate or hinder the curing process, leading to issues such as premature hardening or delayed curing. Professionals need to monitor temperature and, when possible, work in controlled environments to ensure consistent curing.

2. Humidity's Influence:

Humidity levels can affect the adhesion and performance of Fiberglass Body Filler. High humidity might slow down the curing process, while low humidity can impact the filler's bonding properties. Experts often adjust the mixing ratios and application techniques to adapt to varying humidity levels.

3. Rain and Moisture Concerns:

Rain and moisture pose challenges during the application of Fiberglass Body Filler. Moisture can compromise adhesion and lead to poor results. Professionals often take extra precautions by working indoors or using protective measures such as tarps to shield the work area from water.

4. Sunlight and UV Exposure:

UV exposure can have implications on the longevity of the finished restoration work. Fiberglass Body Filler, if not properly protected, can degrade when exposed to prolonged sunlight. Professionals often finish the restoration with appropriate primers, paints, and clear coats that offer UV protection.

5. Wind Disruption:

Wind can be a factor during the application and drying process of Fiberglass Body Filler. Dust and debris carried by the wind might settle on the wet filler, affecting the finish. Professionals combat this by selecting sheltered workspaces or using protective barriers to shield the work area.

6. Temperature Changes during Curing:

Weather conditions can change rapidly, causing temperature fluctuations during the curing process. This can result in uneven curing, affecting the filler's consistency and performance. Professionals might plan their work to coincide with stable weather patterns or use temperature-controlling equipment.

7. Winter and Cold Weather Challenges:

Cold weather brings its own set of challenges, including slower curing times and reduced workability of the filler. Professionals might use heat lamps, warmers, or heated garages to create optimal curing conditions during colder months.

In conclusion, navigating the challenges of different weather conditions is an integral part of achieving successful automotive restoration with Fiberglass Body Filler. Professionals and enthusiasts alike leverage their expertise, along with quality products like SYBON's Filler, to overcome these challenges. By understanding how weather impacts the application and performance, you can approach restoration projects with knowledge and confidence, transforming vehicles into timeless works of art.

How Does SYBON Ensure Quality and Consistency in Their Fiberglass Body Filler Products?

At SYBON, our commitment to excellence extends beyond just being a manufacturer. We understand that in the realm of automotive restoration, quality and consistency are paramount. As a leading producer of Fiberglass Body Filler, we take pride in providing insights into the meticulous processes and practices that underpin the exceptional quality of our products.

1. Rigorous Raw Material Selection:

The journey to quality begins with the selection of raw materials. We meticulously source high-quality resins, fillers, and strengthening agents that meet our stringent standards. This ensures that the foundational elements of our Fiberglass Body Filler are of the highest caliber.

2. Precision Formulation:

Crafting a superior Fiberglass Body Filler involves precise formulation. Our team of experts employs their knowledge and experience to create a formula that balances adhesion, sanding abilities, curing time, and durability. This formula becomes the backbone of our products' performance.

3. Stringent Testing Protocols:

Quality is not just promised; it's proven. Every batch of our Fiberglass Body Filler undergoes rigorous testing. We subject our products to various conditions, simulating real-world scenarios to ensure their resilience, adhesion, and curing properties meet and exceed industry standards.

4. State-of-the-Art Manufacturing Facilities:

Our commitment to quality is mirrored in our state-of-the-art manufacturing facilities. Equipped with cutting-edge technology and maintained to the highest standards, these facilities provide an environment conducive to producing consistently superior Fiberglass Body Filler.

5. Continuous Research and Development:

We believe that innovation is a cornerstone of quality. Our dedicated Research and Development teams continuously explore advancements in materials, formulations, and techniques. This commitment to staying at the forefront of innovation ensures that our products evolve to meet the ever-changing demands of the industry.

6. Quality Control at Every Stage:

From raw materials to the final product, quality control is integrated into every step. Our experts meticulously oversee production processes, conducting regular checks to ensure that each batch of Fiberglass Body Filler aligns with our stringent quality benchmarks.

7. Real-World Testing and Validation:

Our Fiberglass Body Filler isn't just tested in controlled environments; it's put to the test in real-world applications. We collaborate with professionals and enthusiasts, gathering feedback and insights to fine-tune our products based on actual restoration projects.

8. Transparent Communication:

We believe that transparency builds trust. From providing detailed product information to offering guidance on optimal usage, our communication is aimed at empowering our customers to make informed decisions and achieve the best results.

SYBON's Promise:

Quality and consistency are not just buzzwords at SYBON; they are the essence of our brand. Our Fiberglass Body Filler products are a reflection of our dedication to providing professionals and enthusiasts with tools that elevate their restoration projects. With every can of SYBON's Fiberglass Body Filler, you're not just purchasing a product; you're investing in a legacy of excellence.

In conclusion, SYBON's commitment to quality and consistency in our Fiberglass Body Filler products is a testament to our dedication to the art of automotive restoration. From sourcing raw materials to real-world validation, every step in our process is designed to deliver products that stand as beacons of quality, empowering you to achieve restoration excellence.

Are There Any Step-by-Step Tutorials for DIY Enthusiasts on Applying Fiberglass Body Filler?

For DIY enthusiasts passionate about automotive restoration, delving into the world of Fiberglass Body Filler can be both exciting and daunting. At SYBON, we understand that guidance is essential to help you navigate the process with confidence. In this article, we provide a comprehensive step-by-step tutorial on applying Fiberglass Body Filler, empowering you to transform your restoration projects into works of art.

Step 1: Gather Your Tools and Materials:

Before you begin, ensure you have all the necessary tools and materials, including Fiberglass Body Filler, putty knives or spatulas, sandpaper of varying grits, safety gear, and a well-ventilated workspace.

Step 2: Surface Preparation:

The success of your project hinges on proper surface preparation. Clean the area to be repaired thoroughly, removing dirt, grease, and old paint. Sand the surface to create a rough texture that promotes adhesion. Wipe away dust and residue.

Step 3: Mixing the Filler:

Follow the manufacturer's instructions to mix the Fiberglass Body Filler. Typically, it involves combining the resin and hardener in the prescribed ratio. Mix thoroughly until the color is consistent, ensuring a proper chemical reaction for curing.

Step 4: Applying the Filler:

Using a putty knife or spatula, apply the mixed filler to the damaged area. Start with a thin layer to establish a foundation. Gradually build up layers, working in thin applications to avoid excessive buildup. Feather the edges to create a seamless transition.

Step 5: Shaping and Contouring:

Once the filler has cured to a point where it's still workable but not fully hardened, use sandpaper to shape and contour the repaired area. Focus on achieving smooth transitions and matching the original contours of the vehicle.

Step 6: Fine Sanding:

As the filler continues to cure, proceed with fine sanding using progressively finer grits of sandpaper. This step helps refine the contours and create a surface ready for priming and painting. Keep the surface wet while sanding to prevent overheating.

Step 7: Priming:

Apply a suitable automotive primer to the sanded and shaped area. Priming provides a consistent surface for paint adhesion and helps seal the repaired area. Allow the primer to dry according to the manufacturer's instructions.

Step 8: Painting:

Finally, paint the repaired area to match the rest of the vehicle's finish. Follow proper painting techniques, including applying thin coats, allowing adequate drying time between coats, and applying a clear coat for a glossy finish.

Step 9: Buffing and Polishing (Optional):

For a professional touch, you can further enhance the finish by buffing and polishing the painted area. This step adds a layer of shine and ensures a flawless appearance.

Step 10: Admire Your Work:

Step back and admire your completed restoration. Your dedication and attention to detail have transformed a damaged area into a seamless part of the vehicle's aesthetics and structure.

SYBON's Support:

As a DIY enthusiast, you're not alone on this journey. SYBON's Fiberglass Body Filler is designed to facilitate your restoration projects. With its user-friendly application and adherence to different surfaces, you have a reliable ally to achieve professional results in your DIY endeavors.

In conclusion, applying Fiberglass Body Filler is a step-by-step process that combines skill, patience, and the right tools. With this tutorial and SYBON's support, you're equipped to embark on a journey that turns your restoration visions into reality. Transforming vehicles becomes an art form, and every layer of filler applied is a stroke of creativity that adds to the masterpiece.