Home - Products - Car Body Filler - 1K Nitrocellulose Putty(1K NC Putty)

Car Body Filler Series

Lightweight Body Filler

BPO Polyester Putty

CHPO Polyester Filler

High-Temp Filler

Fiberglass Body Filler

1K Nitrocellulose Putty

1K Primer Surfacer

1K Plastic Primer

2K Intermediate Primer

2K Epoxy Primer

Auto Paint Series

Auto Repair Series

View All Products

CONTACT US

1K Nitrocellulose Putty(1K NC Putty)

Welcome to SYBON - Your Source for Innovative Surface Solutions.

Introducing SYBON's Revolutionary 1K Nitrocellulose Putty - Elevate Your Craftsmanship with Excellence.

Discover the Future of Surface Repair with SYBON's 1K Nitrocellulose Putty, also known as 1K NC Putty. Crafted with precision and driven by innovation, our single-component putty redefines the art of flawlessly restoring surfaces. Dive into a world where imperfections vanish, leaving behind a canvas of perfection.

Key Product Features:

1.Seamless Coverage: Conceal small scratches, sand holes, and pinholes effortlessly.

2.Rapid Drying: Minimize waiting time with our fast-drying formula.

3.Effortless Application: Glide on smoothly and achieve a perfect finish with easy sanding.

4.Versatility: Ideal for professionals and DIY enthusiasts, suitable for various materials.

5.Elevate Aesthetics: Transform flaws into artistry, enhance the beauty of every surface.

SYBON is your partner in pushing the boundaries of innovation. Our 1K Nitrocellulose Putty is a testament to our commitment to excellence and the embodiment of limitless possibilities.

Embrace precision, elevate your craftsmanship, and embark on a journey of transformation with SYBON's 1K NC Putty. Explore our website now to witness the outstanding performance and transformative capabilities of our revolutionary product. Redefine the art of surface repair with SYBON - where perfection meets innovation.

| 1K Nitrocellulose Putty(1K NC Putty) | |

|---|---|

| Feature | Single-component putty with good coverage, fast drying, easy to apply and sand, suitable to cover small scratches, sand holes and pinholes. |

| Surface Cleaning | Remove wax, grease, or other contaminations with degreaser. |

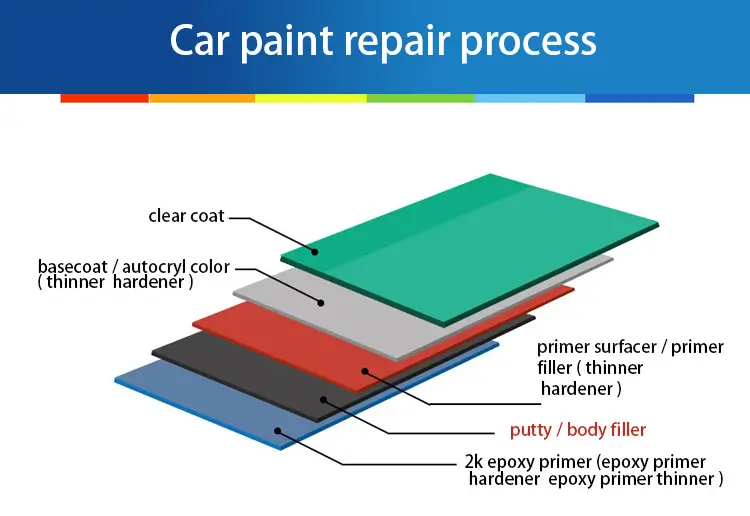

| Substrate | Dried and sanded existing finishes, polyester putty, 1K & 2K primer. |

| Mixing Ratio | Can be used directly. |

| Application Tool | Putty knife, soft rubber or plastic spreader. |

| Dry to Sand | At 25 ℃ , 30 minutes, the thicker application, the longer drying time. |

| Sanding | Wet sanding with P800-P1000; Dry sanding with P600-P800. |

| Shelf Life | 2 years in its original sealed can at cool and dry place at 20 ℃. |

| Packaging | 1L |

| Note | 1.Most of the filler should be sanded out. Only 2%-5% of spreading area could be left. 2.The filler is not suitable to apply directly on bare metals. 3.Spray topcoat directly after sanding in case of small area application. For large areas, it is recommended to use 2K primer prior to topcoat. 4.Please seal the can tightly after use to avoid skinning. |

Contact Details

No 4, Chengye Road, Daliang, Shunde, Foshan, Guangdong, China

+86 13682292799

www.supersybon.com

sales@supersybon.com

SOCIAL

Contact Us

Enquiry will send to our sales team, we will reply you with 24 hours.

Need Any Help ?

Order or no-order we are always here to help you

SYBON: Your Path to Surface Excellence – Distribute or Customize with Confidence

At SYBON, we offer two dynamic avenues for partnership, each designed to cater to your unique business needs. Choose the path that aligns with your goals and embark on a journey of quality and success.

1. Brand Distribution Partnership: Elevate Your Portfolio with SYBON Quality

SYBON proudly presents an opportunity to distribute our premium line of products under your brand. Partnering with us means bringing excellence to your customers through our exceptional 1K Nitrocellulose Putty. Benefit from:

· Proven Quality: Offer your customers a product backed by SYBON's reputation for excellence.

· Diverse Application: Cater to various industries with a versatile solution suitable for a range of surfaces.

· Flawless Finishes: Enhance customer satisfaction with putty that delivers impeccable results.

2. Private Label Option: Your Identity, Our Expertise

Unveil your brand's potential with our private label option. We provide the product – you add the finishing touch:

· Blank Canvases: Receive high-quality products in blank cans, ready for your unique branding.

· Customization: Apply your personalized stickers or labels to create a seamless brand experience.

· Quality Assurance: Rest easy knowing your brand aligns with SYBON's commitment to excellence.

SYBON offers a partnership tailored to your aspirations. Whether you choose to distribute our renowned products or add your unique brand to our exceptional 1K Nitrocellulose Putty, success is just around the corner.

Join us in redefining quality and craftsmanship. Contact us today to explore the endless possibilities that a collaboration with SYBON can bring to your business.

CONTACT US

Enquiry will send to our sales team, we will reply you with 24 hours.

Comprehensive Guide to Nitrocellulose Putty

What is Nitrocellulose Putty and Its Applications?

What are the key benefits of Nitrocellulose Putty in surface repair?

What is the process of applying Nitrocellulose Putty to achieve a seamless finish?

Choosing the Right Nitrocellulose Putty Type for Precise Surface Repairs

Comparing Nitrocellulose Putty to Traditional Repair Methods: Quality and Efficiency Unveiled

How should Nitrocellulose Putty be stored to maintain its quality?

How has Nitrocellulose Putty been used in different industries to achieve outstanding results?

What factors should one consider when sourcing Nitrocellulose Putty to ensure its quality?

What makes SYBON Nitrocellulose Putty stand out in terms of quality and features?

What is Nitrocellulose Putty and Its Applications?

Nitrocellulose putty, commonly referred to as 1K Nitrocellulose Putty or 1K NC Putty, is a versatile and high-performance material that has gained widespread recognition in the realm of surface repair and restoration. In this comprehensive guide, we delve into the essence of nitrocellulose putty, its applications across various industries, and the remarkable advantages it brings to the world of craftsmanship.

Understanding Nitrocellulose Putty:

Nitrocellulose putty is a single-component compound renowned for its exceptional filling and smoothing properties. It is formulated with a blend of nitrocellulose resin, solvents, and other additives, resulting in a unique substance that can seamlessly cover minor imperfections on a wide range of surfaces. This putty has become a preferred choice for professionals and enthusiasts alike due to its ease of use, efficiency, and impeccable results.

Applications Across Industries:

The applications of nitrocellulose putty span a diverse spectrum of industries, each benefiting from its exceptional properties:

Automotive: In the automotive sector, nitrocellulose putty finds its place in repairing small scratches, dents, and surface imperfections on vehicle bodies, ensuring a flawless finish before painting.

Woodworking: Wood craftsmen rely on nitrocellulose putty to fill nail holes, dents, and minor cracks in wooden surfaces, preparing them for finishing touches that highlight the natural beauty of the wood.

Metal Fabrication: Nitrocellulose putty aids in smoothing and restoring metal surfaces, effectively concealing weld seams, sand holes, and blemishes.

Furniture Restoration: Antique and modern furniture restoration benefit from nitrocellulose putty's ability to mask imperfections, enabling restorers to revive pieces to their former glory.

DIY Projects: Home improvement enthusiasts appreciate nitrocellulose putty for its user-friendly application, making it a go-to solution for quick fixes and refinishing tasks.

Advantages of Nitrocellulose Putty:

The key benefits of nitrocellulose putty are manifold:

Effortless Application: Nitrocellulose putty spreads smoothly and evenly, adhering seamlessly to surfaces, minimizing wastage and ensuring consistent results.

Swift Drying: Its fast-drying formulation accelerates repair projects, reducing waiting time between applications and sanding.

Exceptional Coverage: Nitrocellulose putty excels in concealing minor scratches, pinholes, and imperfections, leaving surfaces impeccably smooth.

Versatility: Its compatibility with diverse materials allows for its application on wood, metal, and other substrates, expanding its utility.

Professional Finish: Nitrocellulose putty transforms ordinary repairs into professional-grade outcomes, enhancing aesthetics and value.

In conclusion, nitrocellulose putty stands as a testament to innovation in surface repair. Its applications span industries, and its advantages are undeniable. Whether you're a seasoned professional or a DIY enthusiast, nitrocellulose putty offers a reliable, efficient, and superior solution for achieving flawlessness in every project. Embrace the power of nitrocellulose putty – your key to elevating surfaces to new heights of perfection.

What are the key benefits of Nitrocellulose Putty in surface repair?

When it comes to surface repair, the choice of materials can make all the difference between an average outcome and a flawless finish. Nitrocellulose putty, often referred to as 1K Nitrocellulose Putty or 1K NC Putty, has emerged as a game-changer in the world of surface restoration. In this article, we will delve into the essential benefits that set nitrocellulose putty apart, elevating it to a must-have tool for professionals and DIY enthusiasts alike.

Effortless Application and Seamless Finish:

Nitrocellulose putty boasts an unmatched ease of application. Its smooth consistency allows it to glide effortlessly onto various surfaces, adhering flawlessly to conceal minor imperfections. The result is a seamless finish that enhances the overall aesthetics of the repaired area.

Rapid Drying Formula:

Time is of the essence in any repair project. Nitrocellulose putty is designed with a fast-drying formula that accelerates the process, reducing the waiting time between applications and sanding. This time-saving feature allows you to complete projects more efficiently, boosting productivity.

Impeccable Coverage:

Small scratches, pinholes, and blemishes can compromise the integrity of a surface. Nitrocellulose putty excels in providing exceptional coverage, effectively concealing these imperfections and leaving the surface perfectly smooth and ready for further finishing.

Versatility Across Materials:

One of the standout qualities of nitrocellulose putty is its versatility. Whether you're working on wood, metal, or other substrates, this putty adapts seamlessly. Its ability to adhere to various materials ensures a consistent and professional result across different projects.

Enhanced Aesthetics and Value:

The use of nitrocellulose putty elevates the overall aesthetics of repaired surfaces. By achieving a flawless finish, you not only restore the appearance but also add value to the item or structure being repaired, making it a valuable asset for professionals in various industries.

Ease of Sanding:

Sanding is a crucial step in surface repair, and nitrocellulose putty simplifies this process. Its formulation allows for easy sanding, ensuring a smooth transition from the application stage to the desired final surface texture.

Professional-Grade Results:

Whether you're a skilled craftsman or a DIY enthusiast, nitrocellulose putty empowers you to achieve professional-grade results with every project. Its reliability and consistent performance make it an essential tool in your repair arsenal.

In conclusion, the key benefits of nitrocellulose putty in surface repair are undeniable. From effortless application and rapid drying to impeccable coverage and versatility, it transforms repairs into works of art. With nitrocellulose putty, you're not just repairing surfaces – you're elevating them to new levels of excellence. Make this powerful tool a part of your repair toolkit and experience the transformative difference it brings to your projects.

What is the process of applying Nitrocellulose Putty to achieve a seamless finish?

Achieving a flawless surface repair requires more than just the right materials – it demands a precise and meticulous process. Nitrocellulose putty, also known as 1K Nitrocellulose Putty or 1K NC Putty, is a versatile solution that can transform your repair projects into works of art. In this article, we will guide you through the step-by-step process of applying nitrocellulose putty to achieve a seamless and impeccable finish.

Step 1: Surface Preparation

Before applying nitrocellulose putty, ensure the surface is clean, dry, and free from dust, grease, or contaminants. Use sandpaper or other suitable tools to smoothen the area and create an ideal base for putty application.

Step 2: Putty Application

Prepare the Putty: Open the container of nitrocellulose putty and stir it thoroughly to achieve a uniform consistency.

Apply the Putty: Using a putty knife or a suitable applicator, scoop a small amount of putty and apply it evenly over the damaged or imperfect area. Apply light pressure to ensure proper adhesion.

Feathering Technique: To achieve a seamless blend with the surrounding surface, use a feathering technique. Gradually spread the putty beyond the damaged area, feathering the edges for a smooth transition.

Step 3: Drying and Sanding

Allow the applied nitrocellulose putty to dry according to the manufacturer's recommendations. Once dried, sand the area gently using fine-grit sandpaper. The goal is to achieve a perfectly smooth surface, ensuring that the putty blends seamlessly with the surrounding area.

Step 4: Inspection and Touch-Up

Inspect the repaired area for any remaining imperfections, such as uneven spots or pinholes. If necessary, apply an additional thin layer of nitrocellulose putty, repeating the feathering and drying process.

Step 5: Finishing Touches

After achieving a flawless surface, proceed with the desired finishing touches. This may involve painting, staining, or applying a clear coat, depending on the project requirements.

Tips for Success:

· Work in small sections to ensure precise application and avoid overloading with putty.

· Use a clean and sharp putty knife for smoother application and feathering.

· Follow the recommended drying time to prevent cracking or shrinking of the putty.

· Sand gently and gradually, checking the progress as you go to avoid over-sanding.

· Achieve Perfection with Nitrocellulose Putty.

In conclusion, the process of applying nitrocellulose putty to achieve a seamless finish requires careful attention to detail and a methodical approach. By following these steps and tips, you can harness the power of nitrocellulose putty to transform surface imperfections into flawless works of craftsmanship. Elevate your repair projects with the precision and excellence that nitrocellulose putty brings to the table – a testament to the art of seamless surface restoration.

Choosing the Right Nitrocellulose Putty Type for Precise Surface Repairs

When it comes to surface repair, precision is paramount. Selecting the appropriate materials can make all the difference between a job well done and a subpar outcome. Nitrocellulose putty, commonly known as 1K Nitrocellulose Putty or 1K NC Putty, offers a versatile solution that can be tailored to specific surface repair projects. In this article, we will guide you through the process of choosing the right nitrocellulose putty type to ensure impeccable results.

Step 1: Identify the Surface Type

Begin by identifying the type of surface you intend to repair. Different surfaces, such as wood, metal, or plastic, have varying properties and requirements. Understanding the characteristics of the surface will help you select a nitrocellulose putty that adheres effectively and blends seamlessly.

Step 2: Consider the Repair Scope

Assess the scope of the repair project. Determine whether you are dealing with minor scratches, dents, or larger imperfections. For smaller repairs, a finer-grit nitrocellulose putty may be suitable, while more substantial repairs may require a coarser formulation.

Step 3: Evaluate Drying Time

Nitrocellulose putties come with different drying times. Consider the time you have available for the repair project. If you require a faster turnaround, opt for a nitrocellulose putty with a quicker drying time. This can be particularly advantageous for projects with multiple layers or extensive repairs.

Step 4: Compatibility with Finishing Materials

Keep in mind the finishing materials you intend to apply after the putty is in place. Some nitrocellulose putties may interact differently with paints, stains, or topcoats. Ensure compatibility to achieve a consistent and harmonious final result.

Step 5: Review Manufacturer's Recommendations

Manufacturers often provide guidelines and recommendations for their nitrocellulose putty products. These guidelines may include surface compatibility, recommended application methods, and drying times. Consulting these recommendations can help you make an informed decision.

Step 6: Test and Experiment

If you are uncertain about which nitrocellulose putty type to choose, consider conducting a small test or experiment on a discreet area. Apply the putty and follow the repair process to gauge the compatibility and results before proceeding with the entire project.

Expert Tip:

When in doubt, it's advisable to consult with professionals or experts in the field. They can provide valuable insights based on their experience and expertise, guiding you towards the most suitable nitrocellulose putty type for your specific surface repair needs.

Conclusion: Precision and Perfection

In conclusion, selecting the appropriate nitrocellulose putty type for specific surface repair projects is a crucial step in achieving precision and perfection. By considering factors such as surface type, repair scope, drying time, compatibility, and manufacturer's recommendations, you can confidently choose a nitrocellulose putty that aligns with your project's requirements. Elevate your surface repairs to a new level of excellence with the right nitrocellulose putty – a testament to the art of precision in craftsmanship.

Comparing Nitrocellulose Putty to Traditional Repair Methods: Quality and Efficiency Unveiled

In the realm of surface repair, innovation is a constant driving force, shaping the way we restore and renew various materials. Nitrocellulose putty, known as 1K Nitrocellulose Putty or 1K NC Putty, stands as a testament to this innovation, offering a compelling alternative to traditional repair methods. In this article, we delve into a comprehensive comparison between nitrocellulose putty and traditional repair methods, shedding light on the aspects of quality and efficiency that set them apart.

Quality Comparison: Nitrocellulose Putty vs. Traditional Methods

1. Seamlessness of Finish:

Nitrocellulose putty excels in achieving a seamless finish. Its smooth consistency and ability to feather edges seamlessly create an almost invisible repair, blending flawlessly with the surrounding area. In contrast, traditional methods may leave visible seams or uneven surfaces, detracting from the overall aesthetics.

2. Precision and Detail:

Nitrocellulose putty allows for meticulous precision, enabling repairs in intricate details and small imperfections. Traditional methods might struggle to replicate such precision, potentially compromising the quality of the repair.

3. Consistency and Uniformity:

Nitrocellulose putty offers consistent application and uniform coverage, minimizing the risk of uneven patches or rough spots. Traditional methods may result in variations in thickness and texture, affecting the overall appearance.

Efficiency Comparison: Nitrocellulose Putty vs. Traditional Methods

1. Application Ease:

Nitrocellulose putty's smooth application reduces the time and effort required to achieve an even surface. Traditional methods, depending on the material and technique used, may demand more laborious and time-consuming processes.

2. Drying Time:

Nitrocellulose putty boasts a rapid drying formula that accelerates the repair process. Traditional methods may involve longer waiting periods for drying, prolonging the project timeline.

3. Sanding and Finishing:

Nitrocellulose putty's compatibility with sanding and finishing techniques expedites the process of achieving a smooth surface. Traditional methods might require additional steps or materials to achieve a comparable result.

4. Versatility:

Nitrocellulose putty's versatility across materials reduces the need for different repair methods for various surfaces. Traditional methods often involve specific techniques for each material type.

5. Professional Grade Outcomes:

Nitrocellulose putty enables professionals and DIY enthusiasts to achieve consistently professional-grade outcomes. Traditional methods may demand higher skill levels and experience to attain similar results.

Conclusion: A Shift towards Innovation

In conclusion, the comparison between nitrocellulose putty and traditional repair methods highlights the advantages of innovation in the field of surface restoration. Nitrocellulose putty not only offers superior quality in terms of seamless finish, precision, and uniformity, but also enhances efficiency through its user-friendly application, quick drying, and versatility. While traditional methods have their merits, the efficiency and quality offered by nitrocellulose putty underscore its role as a transformative force in modern surface repair. Embrace the evolution of craftsmanship with nitrocellulose putty – a choice that bridges the gap between traditional excellence and contemporary efficiency.

How should Nitrocellulose Putty be stored to maintain its quality?

Nitrocellulose putty, recognized as 1K Nitrocellulose Putty or 1K NC Putty, is a versatile and high-performance material that holds the power to transform surface repair projects. However, maintaining its quality over time is essential to ensure consistent results. In this article, we delve into the best practices for storing nitrocellulose putty to preserve its quality and extend its lifespan.

Ideal Storage Conditions:

To maintain the integrity of nitrocellulose putty, store it in a cool, dry, and well-ventilated environment. Avoid exposing the putty to extreme temperatures, direct sunlight, or humidity, as these factors can degrade its composition and performance.

Sealed Containers:

Nitrocellulose putty is sensitive to air exposure, which can lead to drying and hardening. Store the putty in its original tightly sealed container. If the original container is compromised, transfer the putty to an airtight container, ensuring no air can enter.

Avoid Contamination:

Prevent cross-contamination by keeping the putty container clean and free from debris. Use clean tools and utensils for handling the putty to avoid introducing contaminants that might affect its quality.

Keep Away from Heat Sources:

Heat can accelerate the drying process of nitrocellulose putty even within a sealed container. Store the putty away from direct heat sources such as radiators, heaters, or heating vents.

Regular Inspection:

Periodically inspect the stored nitrocellulose putty for any signs of hardening, drying, or changes in texture. If you notice any abnormalities, consider using a small test amount before applying it to a project.

Rotation of Stock:

If you have multiple containers of nitrocellulose putty, rotate your stock to ensure that older batches are used before newer ones. This practice helps maintain the freshness and workability of the putty.

Follow Manufacturer Recommendations:

Manufacturers often provide specific storage guidelines for their nitrocellulose putty products. These recommendations may include temperature ranges, shelf life, and storage duration. Adhering to these instructions can significantly contribute to maintaining the putty's quality.

Conclusion: Longevity through Careful Storage

In conclusion, proper storage of nitrocellulose putty is crucial to ensuring its continued quality and effectiveness. By following these guidelines, you can preserve the putty's texture, consistency, and performance, allowing you to achieve consistent and flawless results in your surface repair projects. Elevate your craftsmanship by treating nitrocellulose putty with the care it deserves – a commitment to quality that speaks volumes about your dedication to excellence.

How has Nitrocellulose Putty been used in different industries to achieve outstanding results?

Nitrocellulose putty, also referred to as 1K Nitrocellulose Putty or 1K NC Putty, has ushered in a new era of innovation across diverse industries. Its exceptional properties and versatility have led to remarkable outcomes in surface repair and restoration. In this article, we explore how nitrocellulose putty has been harnessed by various industries to achieve outstanding results, revolutionizing the way surfaces are transformed.

Automotive Industry:

In the automotive world, where aesthetics and precision are paramount, nitrocellulose putty has found a pivotal role. It seamlessly covers minor scratches, dents, and imperfections on vehicle bodies, ensuring a smooth canvas for painting. The exceptional coverage and ease of application provided by nitrocellulose putty contribute to flawless results that enhance the appearance and value of automobiles.

Woodworking and Furniture Restoration:

Wood craftsmen and furniture restorers have embraced nitrocellulose putty to breathe new life into wooden surfaces. It effectively fills nail holes, minor cracks, and imperfections, preparing wood for finishing touches. The putty's compatibility with staining and painting further elevates the quality of the final product, resulting in restored pieces that retain their natural beauty.

Metal Fabrication:

In the realm of metal fabrication, nitrocellulose putty plays a transformative role. It smooths and conceals weld seams, sand holes, and blemishes on metal surfaces, ensuring a polished appearance. Nitrocellulose putty's versatility across metals allows for a consistent and professional finish across a variety of projects.

DIY and Home Improvement:

Nitrocellulose putty has become a staple for DIY enthusiasts and home improvement projects. Its user-friendly application and rapid drying make it an ideal solution for quick fixes, refinishing, and minor repairs around the house. Whether it's restoring furniture or concealing imperfections on walls, nitrocellulose putty empowers homeowners to achieve professional-grade results.

Art and Craftsmanship:

Artists and craftsmen leverage nitrocellulose putty's precision and versatility to create intricate and detailed works. It assists in achieving seamless surfaces and aids in the preparation of artistic creations for painting or finishing. The putty's ability to adhere to various substrates enhances its applicability across a wide range of artistic endeavors.

Conclusion: Reshaping Perfection Across Industries

In conclusion, nitrocellulose putty has transcended its initial purpose to become a transformative force across multiple industries. From automotive refinishing and woodworking to artistry and beyond, its exceptional qualities have led to outstanding results that redefine the standards of perfection. Nitrocellulose putty stands as a testament to the art of surface restoration, a versatile tool that empowers professionals and enthusiasts alike to achieve excellence in every project, regardless of the industry.

What factors should one consider when sourcing Nitrocellulose Putty to ensure its quality?

Sourcing the right materials is the cornerstone of any successful project, and surface repair is no exception. Nitrocellulose putty, known as 1K Nitrocellulose Putty or 1K NC Putty, has gained prominence for its transformative properties. However, ensuring the quality of nitrocellulose putty is paramount to achieving impeccable results. In this article, we delve into the crucial factors one should consider when sourcing nitrocellulose putty to ensure the highest level of quality.

Reputation of the Manufacturer:

The reputation of the manufacturer speaks volumes about the quality of their nitrocellulose putty. Look for manufacturers with a proven track record, positive customer reviews, and a history of delivering reliable and superior products.

Formulation and Composition:

Thoroughly examine the formulation and composition of the nitrocellulose putty. It should contain high-quality nitrocellulose resin, appropriate solvents, and additives that contribute to its performance and durability.

Consistency and Texture:

A quality nitrocellulose putty should have a consistent texture that is smooth and easy to work with. Avoid putties that appear clumpy, gritty, or uneven, as these could affect the final result of your repair project.

Ease of Application and Sanding:

Consider the ease of application and sanding. A good nitrocellulose putty should spread evenly and adhere well to various surfaces. It should also sand smoothly without clogging sandpaper or leaving behind excessive residue.

Drying Time and Shrinkage:

Evaluate the drying time and shrinkage rate of the putty. Opt for a nitrocellulose putty that dries within a reasonable timeframe and minimizes shrinkage to prevent cracks or imperfections after drying.

Compatibility with Finishing Materials:

Ensure that the nitrocellulose putty is compatible with the finishing materials you intend to use, such as paints, stains, or clear coats. Incompatibility can lead to adhesion issues or undesirable interactions.

Technical Support and Resources:

Look for manufacturers that provide comprehensive technical support and resources. This includes detailed instructions for application, troubleshooting guides, and customer service assistance in case of any issues.

Conclusion: Elevating Excellence Through Quality Sourcing

In conclusion, the process of sourcing nitrocellulose putty is a critical step towards achieving excellence in surface repair. By considering factors such as manufacturer reputation, formulation, ease of application, compatibility, and technical support, you can ensure that the nitrocellulose putty you choose is of the highest quality. Embrace the commitment to quality sourcing, and empower your repair projects with nitrocellulose putty that embodies the essence of precision and craftsmanship.

What makes SYBON Nitrocellulose Putty stand out in terms of quality and features?

In the realm of surface repair and restoration, the choice of materials can make a world of difference in achieving flawless results. SYBON Nitrocellulose Putty, renowned as a game-changer, stands at the forefront of innovation and craftsmanship. In this article, we delve into what makes SYBON Nitrocellulose Putty truly exceptional, highlighting the qualities and features that set us apart from the rest.

Superior Formulation and Composition:

At the heart of SYBON Nitrocellulose Putty lies a meticulously crafted formulation. Our putty is expertly blended with high-quality nitrocellulose resin, carefully selected solvents, and premium additives. This composition ensures optimal adhesion, smooth application, and impeccable results on various surfaces.

Unrivaled Ease of Application:

SYBON Nitrocellulose Putty redefines the application process. Its velvety-smooth texture glides effortlessly onto surfaces, allowing for precise placement and feathering. This ease of application minimizes user effort and ensures a seamless finish, even in intricate details.

Efficiency in Drying and Sanding:

Time is of the essence, and SYBON Nitrocellulose Putty recognizes this. Our fast-drying formula expedites the repair process, reducing waiting times between applications and sanding. The putty's compatibility with sanding techniques guarantees a smooth transition from application to the desired final surface texture.

Exceptional Coverage and Blending:

SYBON Nitrocellulose Putty boasts outstanding coverage capabilities. It expertly conceals minor scratches, pinholes, and imperfections, ensuring a flawlessly restored surface. The putty's ability to seamlessly blend with surrounding areas results in a finish that appears untouched by repairs.

Versatility Across Industries:

What truly distinguishes SYBON Nitrocellulose Putty is its versatility across industries. From automotive refinishing to woodworking, furniture restoration, and beyond, our putty adapts seamlessly to various materials and substrates. This adaptability makes it a reliable choice for professionals and DIY enthusiasts alike.

Sourced to Perfection:

SYBON Nitrocellulose Putty is meticulously crafted using premium materials and cutting-edge techniques. Our commitment to quality extends beyond formulation to encompass sourcing, production, and rigorous quality control measures, ensuring that every batch meets the highest standards.

Dedicated Support and Expertise:

As a manufacturer dedicated to customer satisfaction, SYBON provides unparalleled technical support and resources. Our team of experts is readily available to assist with application guidance, troubleshooting, and ensuring that you achieve the best possible results with our nitrocellulose putty.

Conclusion: Elevate Your Craftsmanship with SYBON Nitrocellulose Putty

In conclusion, SYBON Nitrocellulose Putty shines as a beacon of excellence in the realm of surface repair. Our commitment to superior formulation, ease of application, efficiency, and unmatched versatility makes us the preferred choice for professionals seeking outstanding results. Elevate your craftsmanship and transform surface repair into an art form with SYBON Nitrocellulose Putty – a testament to quality, innovation, and the pursuit of perfection.