Best 2K Epoxy Primer: A Practical Guide for Importers, Distributors, Fleets & Repair Shops

When professional refinishers, fleet managers, and distributors search for the best 2K epoxy primer, they want a product that delivers dependable corrosion resistance, strong adhesion to varied substrates, ease of application, and consistent results — without an inflated price tag. SYBON understands those needs. As a leading Chinese automotive coatings manufacturer focused on one-stop procurement and reliable quality, SYBON offers a 2K epoxy primer that competes with major brands on performance while giving you better cost-efficiency for your local market.

What makes a 2K epoxy primer “the best”?

A top-tier 2K epoxy primer must excel in several areas important to B2B buyers:

- Corrosion protection — long-lasting barrier against rust, especially for bare metal and repaired panels.

- Adhesion — strong bonding to steel, aluminum, plastic repair substrates, and existing OEM finishes.

- Chemical resistance — withstands fuels, cleaners, and common shop solvents during service life.

- Sandability — easy to sand to a smooth profile for subsequent filler or topcoat application.

- Compatibility — works with a wide range of topcoats (single-stage, basecoat/clearcoat, waterborne systems).

- Pot life & workability — predictable mixing ratios, pot life suitable for shop workflows, and stable performance across batches.

- Value — consistent quality at a price point that supports distributor margins and competitive local pricing.

SYBON’s 2K epoxy primer was developed to address all these priorities while giving distributors and repair shops a product that helps them win business.

Key features of SYBON’s 2K epoxy primer

- Two-component epoxy chemistry for superior corrosion resistance and long-term durability.

- Excellent adhesion to ferrous and non-ferrous substrates and to typical fillers and bodywork materials.

- Fast film cure and good sandability, enabling efficient workflow in busy shops.

- Flexible compatibility with common automotive topcoats — solventborne systems.

- Consistent batch quality — manufactured to strict quality control standards so distributors and end users get predictable results.

Typical applications

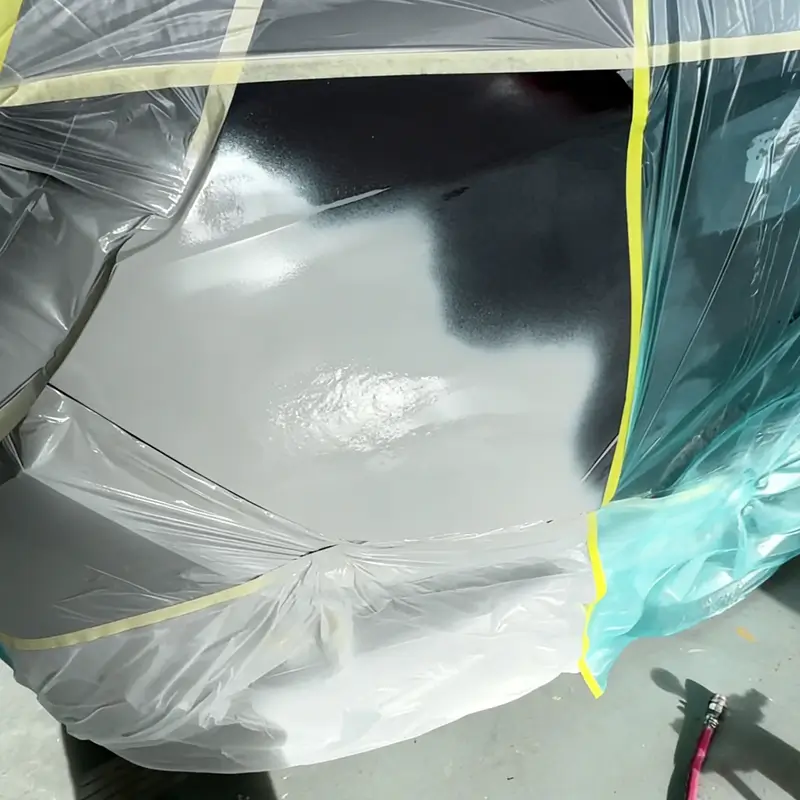

- Full panel refinishes and spot repairs on passenger vehicles and commercial fleets.

- Corrosion-prone areas — rocker panels, wheel wells, and bare metal after rust removal.

- Prepping welded or repaired bodywork before guide coat or high-build primer/filler.

Practical specs & shop tips (general guidance)

- Mix ratio: Follow the technical data sheet for exact resin-to-hardener ratio. Typical 2K epoxy primers are mixed by volume (e.g., 4:1 or similar) — always confirm with SDS/TDS.

- Pot life: Varies by temperature; mix only what you will use within the pot life window to avoid waste.

- Application: Apply 1–2 medium coats; flash between coats per TDS. Target a tack-free cure before sanding.

- Drying & sanding: Allow recommended cure time; epoxy primers typically sand well after a short dry time but aggressive sanding is usually best after full cure for optimal finish.

- Storage: Keep components sealed and stored in a cool, dry place away from direct sunlight. Observe shelf-life info on containers.

Why SYBON is a smart choice for distributors and repair shops

- Competitive pricing without cutting corners: SYBON’s production scale and optimized processes let us offer high-performance primers at a price that improves distributor margins and shop profitability.

- One-stop procurement: Beyond epoxy primers, SYBON supplies a full range of automotive refinish products — putties, clear coats, thinners, abrasives and accessories — making stocking and logistics simpler.

- Quality parity with big brands: While SYBON may not yet be a household name in every market, our formulations and QC meet professional standards comparable to established brands — giving you a product that performs when it matters.

- Support for partners: We value distributor relationships. SYBON provides product documentation, application guidance, and sample support to help you demonstrate product performance to your customers.

How distributors and fleet owners can test SYBON

If you’re an importer, distributor, bodyshop owner, or fleet manager interested in evaluating the best 2K epoxy primer for your market, SYBON welcomes you to request samples. Testing recommendations:

1. Perform adhesion and corrosion panels alongside your current primer.

2. Check sandability and compatibility with your preferred topcoats.

3. Run real-world field tests on a repaired panel from your fleet or repair jobs.

Call to action

SYBON is actively seeking global distributors and local partners. If you want a high-quality, cost-effective solution for automotive refinish work, we encourage you to request samples and start comparative testing. SYBON is ready to support your market entry — please contact us via our website and send an inquiry email; we will respond within 24 hours to discuss samples, pricing, and partnership terms.

Choosing the best 2K epoxy primer is about balancing performance, reliability, and cost — SYBON delivers on all three. If you want a product that helps you compete on quality and price in your local market, SYBON is ready to partner with you.

Source of this article:https://www.supersybon.com/

Get to know us through more channels:

Facebook, Tiktok, Instagram, youtube.